A couple weeks ago, a team of WVU students and I traveled to Utah to compete in the University Rover Challenge (URC) for the first time. It has been 5-years since I was last at a robot competition. This time, we have a new group of passionate and talented students, which brought back a lot of memory and excitements. We ended up doing well for a first-time team, but that was not without struggles and some luck.

Going to a robot competition is to get out of ones’ normal life routine. In a short a few days, unexpected events are rapidly unfolding in front of everyone’s eyes, followed by rapid and intense problem solving by the team members. In this post, I will mention just a few of these surprises.

Imagine you are sending a rover to Mars for a science mission. Your rover needs to be in other people’s hands for transportation and payload integration. It has to survive the rocket launch, months of interplanetary travel, and the short but horrifying landing process. It may not end up in the exact location on Mars as you hoped. Once it’s there, there is only so much you can do about the rover, and things start to break as the rover moves from one place to another …

URC was a bit like that. As a good robot challenge should be, there are many elements of surprises. Some of these surprises are imposed by the physical world, like a real Mars mission, and some are exclusively for the first timers like us.

Our launch vehicle was a brown UPS truck. We packed everything in five wooden crates and a cardboard box, with almost 300kg of gear. After traveling on the Earth surface for three days the shipment arrived at Denver. A two-person team picked it up with a van and completed the remaining 7-hour journey.

Several parts broke during this trip, mostly 3D printed ones. Luckily, we brought backups. Our 3D printer also had a motor mount broken. A team member (Tyler) zip tied the motor to print a new part to fix the problem, practically creating a self-repairing 3D printer. To our surprise, all the steel bolts on the rover were heavily rusted, as if the UPS truck took a sea route.

Getting the robot ready for the first two missions (Equipment Servicing and Autonomy) on the first competition day took a long time. Some testing were pushed to after dark. At close to 11pm (1pm Easter time), things started to look really good with everything working. When powering down the system, an (unpowered) GPS cable fall into the electronics box and got close (but not quite touching) the power distribution board. After a small flash under one of the darkest night skies in the US, everything went quiet.

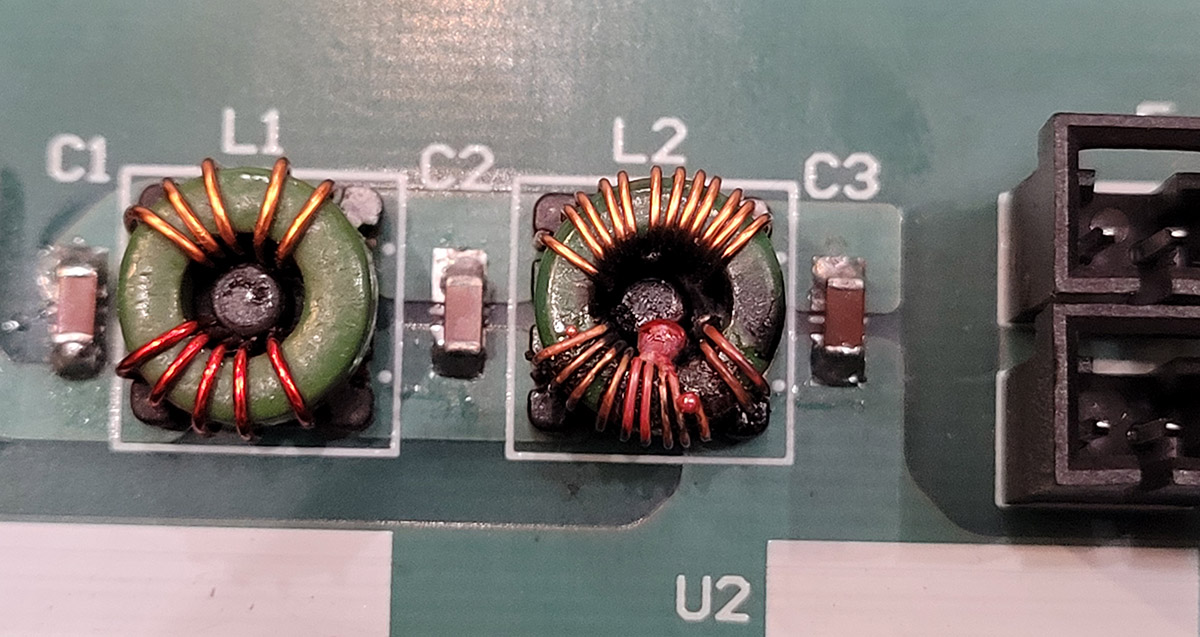

The night of excitement renewed after the incident and sleep was no longer important. Close inspection of the power board revealed that an inductor melted down. The inline fuse was still intact and there was no way to tell if the electronics downstream (e.g., computer) were still ok. Swapping out the power board with a backup piece took some careful deliberation and planning. Luckily everything worked and there were still over 2 hours left to sleep before we need to get on the road.

It was a small miracle that the robot worked for the Equipment Serving task without having a chance to do a full system testing after putting everything back together. We probably wouldn’t do much better than what we did without more in-depth understanding of the tasks, which could only be acquired through being there.

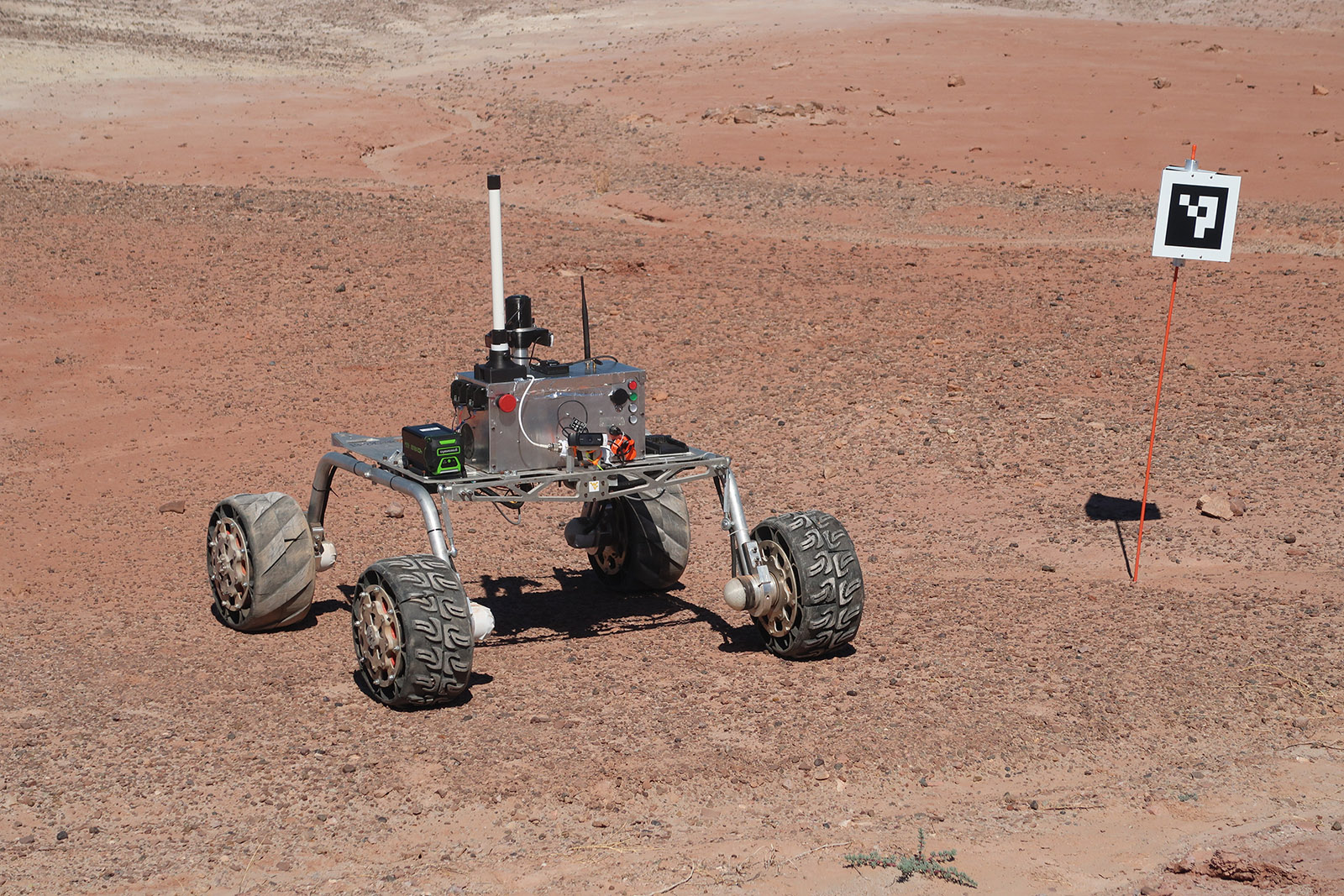

The Autonomy task was more … dramatic, for a lack of better word. The robot held its position (like the picture below) for almost the entire duration of the 30-minute mission. At the very last moment, it took off and reached its first waypoint. For us outside of the command station trailer, a motionless robot can trigger many emotions and speculations. For the members inside the trailer, they were in a frantic problem-solving mode. Clearly, the time went by at very different rates just a few meters apart.

What turned out to be happening was that the terrain map loaded on the rover was centered around the habitats of MDRS. For the actual URC competition, the organizers split the four different missions at three locations about 1km apart. The starting point of the autonomy mission was just outside of our prior map. Knowing it’s not on the map, the robot did not know what to do. It took the team members just a few minutes to diagnose the problem, and then many trials and errors to place a blank map in the right place so the robot can move. It worked! I have seen many “autonomous” robots made up its mind to not go anywhere during the competitions …, this was the first time that a robot changed the mind (with some human help, of course).

With a bit more time and experience, we were better prepared for the next two missions on the following days: Science, and Extreme Retrieval and Delivery. There was no shortage of surprises and issues, but the team (and the rover) held up well.

An adventure like the URC trip teaches us the meaning of real-world engineering. To know a system works, we need to put it through the test of truly new environments and unexpected situations, out of the control of the robot designers. The thought that we shipped a rover to one of the most uninhabitable deserts in the continental US thousands of kilometers away and still managed to make it work in all four missions is quite satisfying. Many other teams, especially international ones, had to cope with even harder constraints, like designing the rover to fit in airline carry-on cases.

When a new problem arises during a competition, and it almost certainly will, the problem needs to be understood and solved quickly, either by the robot itself or by team members. Luckily, robot designers and programmers are trained problem solvers, although their performance can be further improved with more systematic approaches. For autonomous robots? problem-solving is a much harder challenge and perhaps the greatest gap in the current robotics research.

Here is a group photo of the team along with our judge (second from the left), taken in front of a MDRS habitat after the Extreme Retrieval and Delivery mission.